Introduction:

Long-term usage of personal protection equipment (PPE) or wearable technology depends on comfort and fit. Products like the Worktunes headphones, which are meant to offer both hearing protection and music or audio playback, especially fit this. However, like many off-the-shelf items, the fit may not always be ideal for every user. Designing and 3D printing bespoke ear attachments for Worktunes headphones is one creative idea. 3D printing lets you make ear clips that exactly suit your ears, hence enhancing comfort and performance. This article will look at how to create, 3D print, and apply unique Worktunes ear clips to improve your experience.

Why Think About 3d-Printed Ear Clips for Worktunes?

Workers in loud settings, like those using 3M’s Worktunes headphones. These headphones let you listen to music or make calls while also providing hearing protection. Although they are meant for comfort, some users may find that the basic ear cups or ear clips do not provide the perfect fit. Custom 3d-printed ear clips can solve this problem by providing a solution suited to particular requirements.

Main Advantages of 3d-Printed Ear Clips for Worktunes:

- Tailored Fit: 3D printing lets you construct ear clips meant especially for your ear shape and size, hence guaranteeing a more comfortable fit. Especially during long shifts or extended use, custom ear clips might aid to lower pressure spots and enhance general comfort.

- A properly fitting ear clip can enhance the sound-isolating or noise-cancelling capabilities of the headphones.

- 3D printing bespoke ear clips at a fraction of the cost saves you from buying extra accessories.

- Rapid Prototyping: 3D printing lets you rapidly construct, test, and improve designs, hence helping you to discover the ideal fit.

Designing Custom Ear Clips for Worktunes Headphones

Creating your ear clips for Worktunes headphones calls for a rudimentary knowledge of 3D modelling and the application of 3D design tools. Here is a step-by-step instruction to assist you in beginning:

1. Ear Measurement

Accurate ear measurements are the first step in creating bespoke ear clips. Measuring your ears guarantees that the clips will fit correctly, as everyone’s ear shape and size are different. A flexible measuring tape will let you note the circumference of your ears or take thorough photographs of them to catch their shape.

2. Develop a three-dimensional model

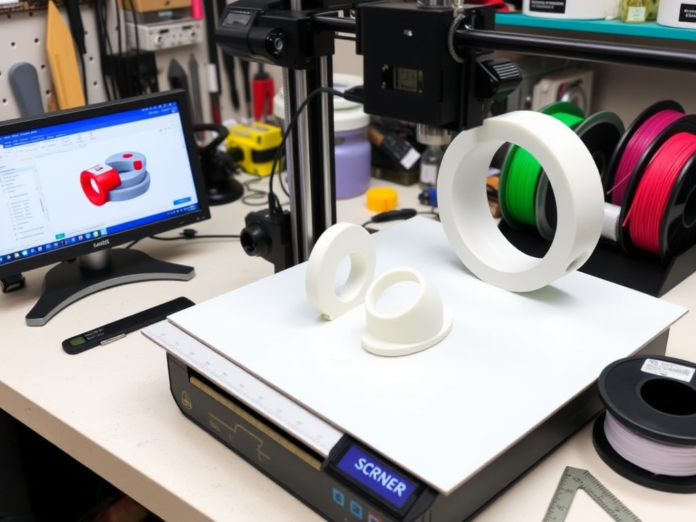

3D modelling tools like Fusion 360, Tinkercad, or Blender will help you to make the ear clips. By combining shapes and changing sizes, these tools let you create bespoke parts. You should design the ear clips to match the ear cups of your Worktunes headphones and offer a comfortable fit around your ears.

When designing the model, think about the following:

- The ear clip should fit the contour of the Worktunes ear cups to ensure they stay in place firmly.

- You may create extra padding or cushioning within the ear clip to enhance comfort if you like.

- Mounting Locations: Create the clip with mounting locations that allow it to fasten firmly to the Worktunes headphones. You might have to add holes or slots to line up with the headphone body.

- The design should allow the clip to bend slightly for a tight fit, yet be strong, since ear clips need to be both robust and flexible.

3. Export the Model for 3D Printing

When you are happy with your ear clip design, save the file in either STL or OBJ format, which works with most 3D printers. Should your 3D printer find your design too complicated, think about reducing it or dividing the design into smaller components that may be combined later.

4. Select the Correct Printing Material

Your ear clips’ flexibility, strength, and lifetime will be defined by the material you select. Among the finest materials for printing ear clips are:

- PLA (Polylactic Acid): Ideal for low-stress components, this non-toxic polymer is simple to print. Although not the most robust alternative, it might be suitable for casual use or prototypes.

- ABS (Acrylonitrile Butadiene Styrene): A stronger polymer that can tolerate higher temperatures and more wear and tear, it’s suitable for more robust ear clips that must withstand regular use.

- PETG (Polyethene Terephthalate Glycol): PETG strikes a fair mix between durability and flexibility. It is perfect for components that must endure bending without breaking, since it is impact-resistant.

5. Print the Ear Clips in 3D

Your ear clips are ready to print once you have selected your filament and prepared your 3d model. Ensure your 3D printer is calibrated and ready to print. Set your layer height to 0.2 mm for smooth results if you want a nice grade print. For greater robustness and longevity, you can also print the ear clips with a larger infill percentage, e.g., 50-70%.

6. Post-Processing

Once the print is finished, take the ear clips from the print bed and tidy up any jagged edges. A tiny file or sandpaper could help you to polish the surfaces. Carefully take out any support material from the printing process on the ear clips.

Examining the 3d-Printed Worktunes Ear Clips

It’s time to put your bespoke ear clips to use. Put the clips on your Worktunes headphones and see if they fit. Think about the following while testing:

- Comfort: Do the clips feel comfy on your ears? Change the design to relieve pressure or improve the fit as needed.

- Ensure the clips stay firmly fastened to the headphones during motion. If they seem loose, you may need to adjust the size of the clip or add additional features, such as a locking system.

- Do the ear clips improve the noise isolation or noise-cancelling capabilities of the Worktunes headphones? If the clip doesn’t fit properly, consider changing its design to enhance ear sealing.

READ MORE – VOC-Free 3D Printer Filament: A Sustainable Choice for Safe Printing

FAQs:

- May I 3D print ear clips for several other kinds of headphones?

Indeed, 3D printing lets you design unique ear clips for all sorts of headphones. Make sure the clips fit tight and you measure the ear cups. - What material is ideal for 3D printing ear clips for headphones?

ABS or PETG are the ideal materials for durability and flexibility. For prototypes or light-duty uses, PLA is also acceptable. - How can I make sure my bespoke ear clips fit comfortably?

Measure your ears precisely and change the design of the ear clips to fit your ear shape. Consider adding cushioning or padding for extra comfort. - Is a dual-extruder 3D printer required for this project?

A single extruder printer should be enough. If you need to, you can print the ear clips in one piece and add padding or cushioning during the post-processing stage. - How long does it take to 3D print personalised ear clips?

The complexity and size of your design affect print times. A print might take, on average, anywhere from two to six hours to finish.

Conclusion:

Designing unique 3d-printed ear clips for Worktunes headphones can significantly improve comfort, fit, and utility. 3D printing is a reasonably priced and adaptable option, whether you want to customise your headphones, need a better fit for long hours of use, or want better sound isolation. Following the procedures described in this manual will let you create, print, and use bespoke ear clips fit for your requirements.